Improving Vacuum Glazing Safety and Quality via Systematic Root Cause Analysis

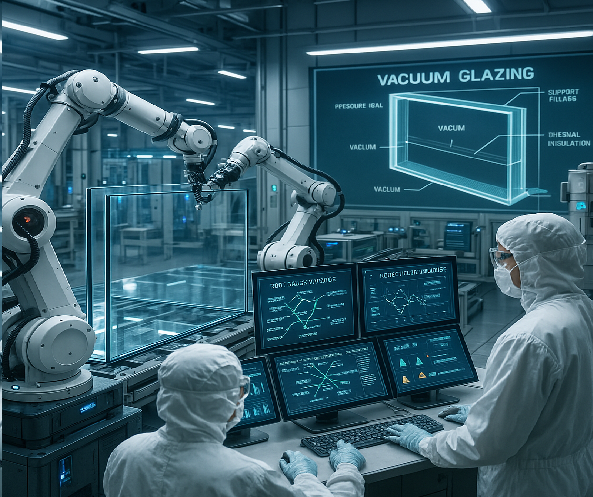

Advanced glazing technologies have revolutionized building safety standards through innovative insulation solutions that maintain structural integrity while delivering superior thermal performance. Vacuum glazing is a representation of how advanced window manufacturing technology has become. It eliminates air molecules between the glass panes, preventing heat transfer.

This technology incorporates precision-engineered support structures and specialized sealing materials that must withstand significant pressure. The manufacturing process requires stringent quality control measures to ensure consistent performance and prevent potential failure modes that could compromise building safety. Modern vacuum glazing systems undergo extensive testing protocols to validate their durability, thermal efficiency, and resistance to environmental stresses.

Systematic Root Cause Analysis Methodologies

Root cause analysis provides structured approaches for identifying underlying factors that contribute to safety incidents and quality failures across various industries and applications. These methodologies move beyond surface-level symptoms to uncover fundamental issues that, when addressed, prevent recurring problems and improve overall system reliability. Effective root cause analysis requires systematic data collection, analytical thinking, and collaborative problem-solving approaches that engage multiple stakeholders.

The fishbone diagram technique enables investigation teams to visualize potential causes across different categories, including:

- Human factors

- Equipment issues

- Environmental conditions

- Process variations

This structured approach ensures comprehensive examination of all possible contributing factors while maintaining focus on actionable solutions.

Human Factors and Organizational Influences

Human performance plays a critical role in safety outcomes, with research indicating that human factors contribute to the majority of workplace incidents and quality failures. Understanding cognitive limitations, decision-making processes, and environmental influences helps organizations design systems that support reliable human performance while minimizing error opportunities.

Organizational culture significantly impacts safety performance through its influence on communication patterns, risk tolerance, and resource allocation decisions. Companies with strong safety cultures demonstrate consistent leadership commitment, open communication channels, and proactive hazard identification processes that prevent incidents before they occur.

Process Analysis and System Design

Process design deficiencies often create conditions that increase the likelihood of errors and failures, making systematic process analysis essential for preventing future incidents.

Effective process design incorporates error prevention principles, redundancy measures, and fail-safe mechanisms that maintain system integrity even when individual components fail.

Change management processes require careful consideration of potential unintended consequences that could introduce new risks or eliminate existing safeguards. Comprehensive change analysis evaluates impacts across interconnected systems and ensures that modifications enhance rather than compromise overall safety performance.

Technology Integration and Failure Prevention

Advanced monitoring systems provide real-time visibility into process conditions and equipment performance, enabling early detection of potential problems before they escalate into serious incidents. These systems utilize sensors, data analytics, and predictive algorithms to identify patterns that indicate developing failure modes.

Maintenance strategies based on condition monitoring and predictive analytics help prevent equipment failures that could compromise safety or quality outcomes. These approaches optimize maintenance schedules based on actual equipment condition rather than arbitrary time intervals, improving reliability while reducing costs.

Automated Safety Systems with Built-In Redundancy and Fail-Safe Protections

Automated safety systems incorporate multiple layers of protection that activate independently to prevent or mitigate the consequences of potential failures. Redundant sensors, diverse protection mechanisms, and fail-safe designs are usually installed to these systems. Its goal is to maintain protective function even when individual components malfunction.

Training programs that emphasize critical thinking and systematic problem-solving skills enable employees to recognize developing problems and take appropriate corrective actions before incidents occur.

Are you currently making YouTube videos? Thinking about how to examine the effects of your content?

Are you currently making YouTube videos? Thinking about how to examine the effects of your content?