Behind the Label: Why Safety Testing Matters in the Supplement Industry

Supplements have become a daily ritual for millions of people, from vitamins and herbal blends to protein powders and appetite syrups. The industry continues to grow rapidly, promising everything from better health to enhanced appearance. Yet, behind those glossy bottles lies a critical question: how safe are these products? As consumers chase quick results and aesthetic goals, safety testing has become more than a technical requirement—it’s a public concern that demands attention.

The appetite syrup trend highlights the urgency of strict safety measures. Products like super apeti plus for weight gain have attracted significant interest among consumers looking for fast solutions to boost their appetite or body mass. However, popularity often brings imitation. Without proper quality control, counterfeit or contaminated versions can enter the market, posing serious health risks. This is why ingredient verification and labeling transparency are more than marketing—they’re a matter of public safety.

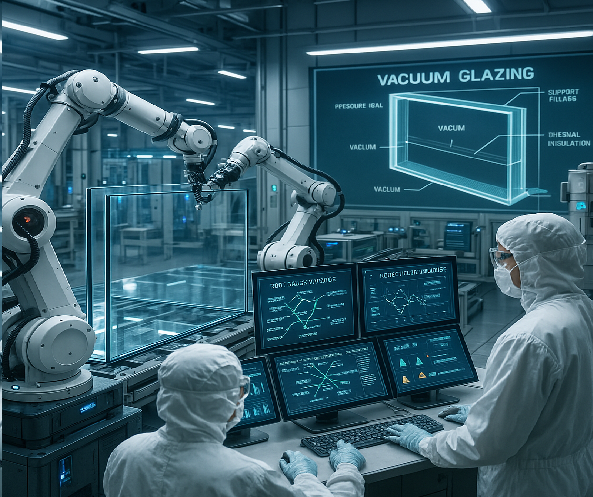

The Role of Quality Control

Quality control forms the foundation of supplement safety. Every capsule, syrup, or powder must undergo rigorous testing to ensure that what’s printed on the label matches what’s inside. Reputable manufacturers follow Good Manufacturing Practices (GMP) and often partner with independent laboratories to verify purity and potency. Contaminants such as heavy metals, bacteria, or undeclared pharmaceutical ingredients are potential threats that only proper testing can identify. To understand why implementing strong quality control systems benefits both safety and reputation, you can read more about it here.

When quality control is overlooked, consumers pay the price. Cases of supplements containing unapproved ingredients or harmful stimulants continue to surface. This is especially concerning in online markets, where anyone can sell a product without clear oversight. For a consumer, the label may promise natural ingredients, but the real content might tell another story.

Ingredient Verification and Label Accuracy

Ingredient verification ensures that supplements deliver exactly what they claim. Independent testing laboratories often analyze product samples to confirm ingredient identity and concentration. This process prevents mislabeling and protects consumers from unknown side effects. Clear, accurate labels allow buyers to make informed decisions about what they put into their bodies.

Transparency should be non-negotiable in supplement labeling. When consumers see a list of ingredients, they trust that it’s truthful. Labels that omit certain additives, or exaggerate their effects, break that trust. Regulators like the FDA require manufacturers to disclose active and inactive ingredients, serving sizes, and potential allergens. Still, enforcement can be challenging, especially for imported products or those sold exclusively online.

Why FDA Compliance Matters

FDA compliance acts as a safety net against potential health hazards. Although the FDA doesn’t pre-approve supplements before they hit the market, it can take action against unsafe or falsely labeled products. Manufacturers are responsible for ensuring that their supplements are safe and that any claims are truthful and backed by evidence. Testing for contaminants and ensuring correct labeling are key steps in maintaining compliance.

When a supplement meets FDA guidelines, it earns consumer trust. For instance, testing verifies whether a product like super apeti plus for weight gain is safe for consumption and meets declared standards. This transparency reassures users that they’re not risking their health for short-term results. Without oversight, the door opens for unregulated supplements that can cause long-term harm.

The Appetite Syrup Trend: A Cautionary Tale

The recent rise of appetite syrups has created both excitement and concern. These products promise rapid weight gain, improved appetite, and better body curves. But quick fixes often come with hidden costs. Reports of fake or low-quality syrups flooding online markets highlight the lack of consistent testing standards. Some versions contain undeclared drugs or allergens, while others have inaccurate dosage information.

Consumers can protect themselves by verifying authenticity before purchase. Checking for third-party lab results, FDA registration, and batch numbers can help confirm a product’s legitimacy. Brands that publish transparent testing reports demonstrate accountability, showing that their ingredients and processes are safe and verified.

The Future of Supplement Safety

The supplement industry’s future depends on stricter oversight and consumer awareness. With new trends emerging every year, from herbal boosters to appetite stimulants, testing will remain the cornerstone of responsible production. Manufacturers who invest in quality assurance and open communication will stand out as trustworthy players in a crowded market.

Ultimately, safety testing is not just a regulatory checkbox—it’s a commitment to consumer health. Whether it’s vitamins, herbal blends, or super apeti plus for weight gain, supplements should be developed with the same care as any other product meant for human consumption. A clear label backed by verified science ensures peace of mind and long-term wellness. Behind every supplement lies a responsibility: to protect the people who believe in its promise.

Every year, thousands of red-carpet and corporate events in New York showcase their identity through large, dramatic backdrops. These banners do more than frame photo moments. They carry logos, sponsors, and a sense of occasion. Yet behind their striking visuals lies a serious responsibility. Materials must be safe, frames must hold steady, and installation must comply with regulations that keep both guests and staff secure.

Every year, thousands of red-carpet and corporate events in New York showcase their identity through large, dramatic backdrops. These banners do more than frame photo moments. They carry logos, sponsors, and a sense of occasion. Yet behind their striking visuals lies a serious responsibility. Materials must be safe, frames must hold steady, and installation must comply with regulations that keep both guests and staff secure.